Brief

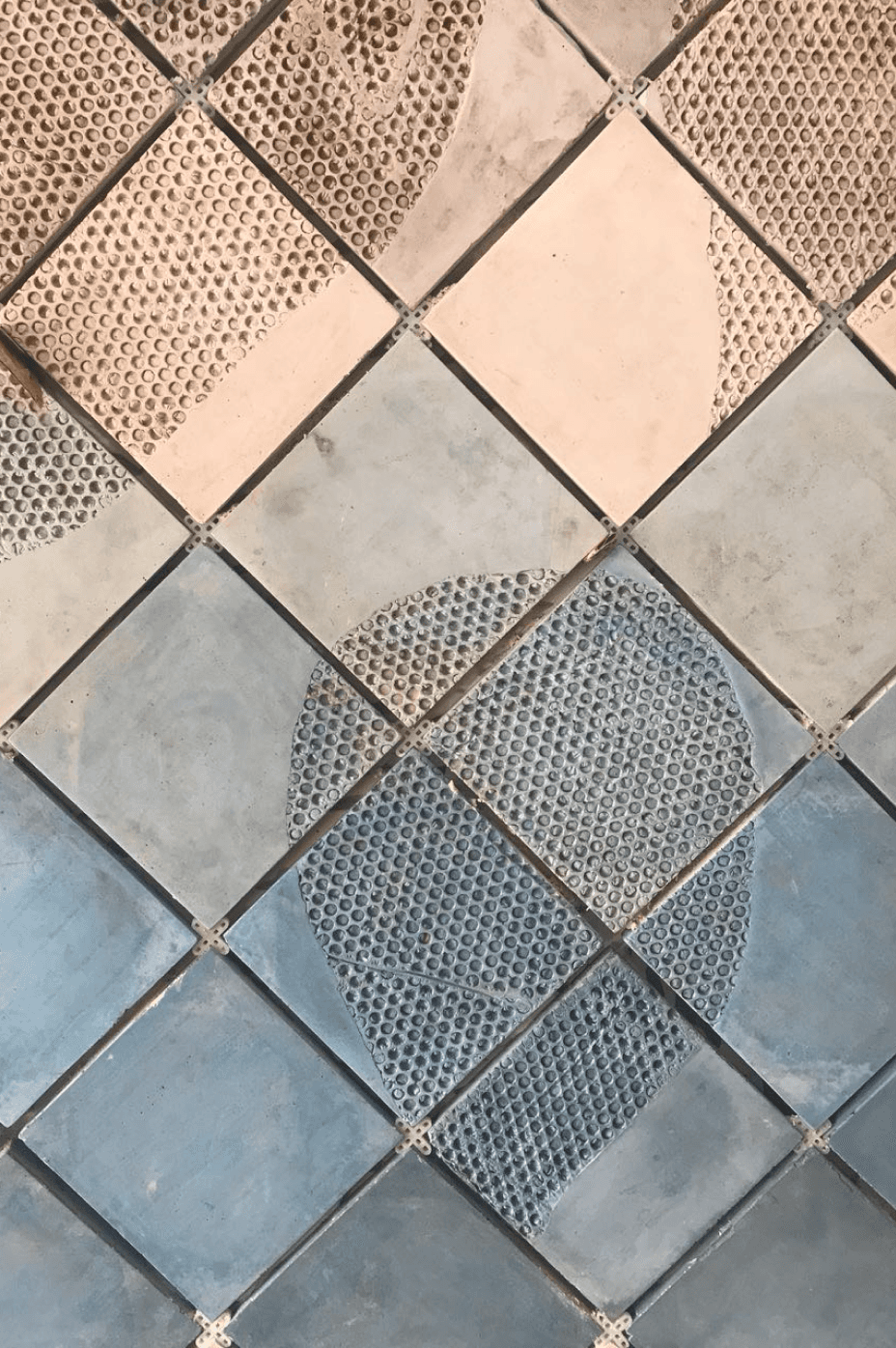

Casting cement tiles of different shades in gradation for a 3' x 6' wall mural in a ceramic import export office

Hands on

The process included experimenting with cement, various shades of oxide, different ways to create pattern on the tiles.

Pattern exploration by casting different leaves

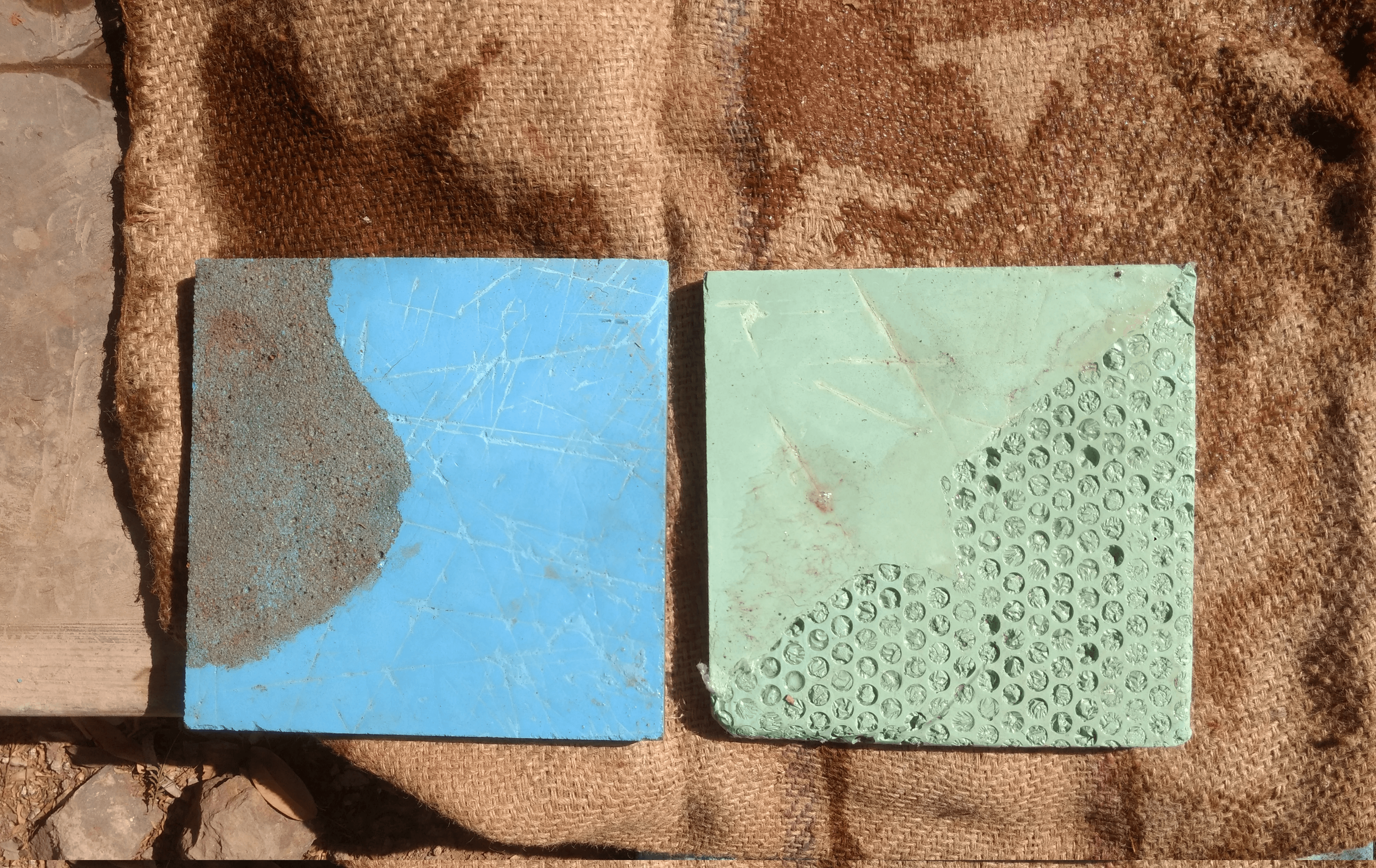

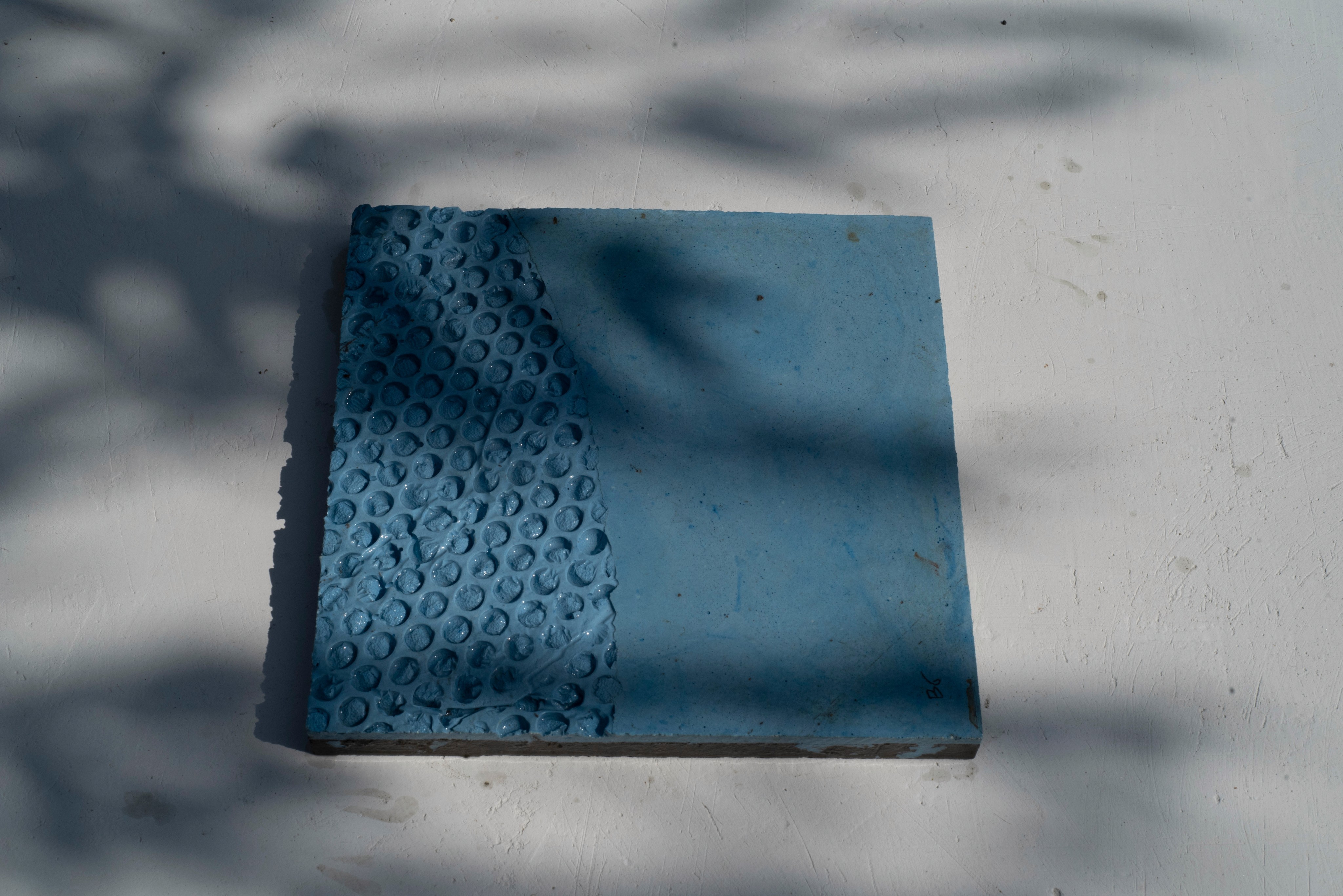

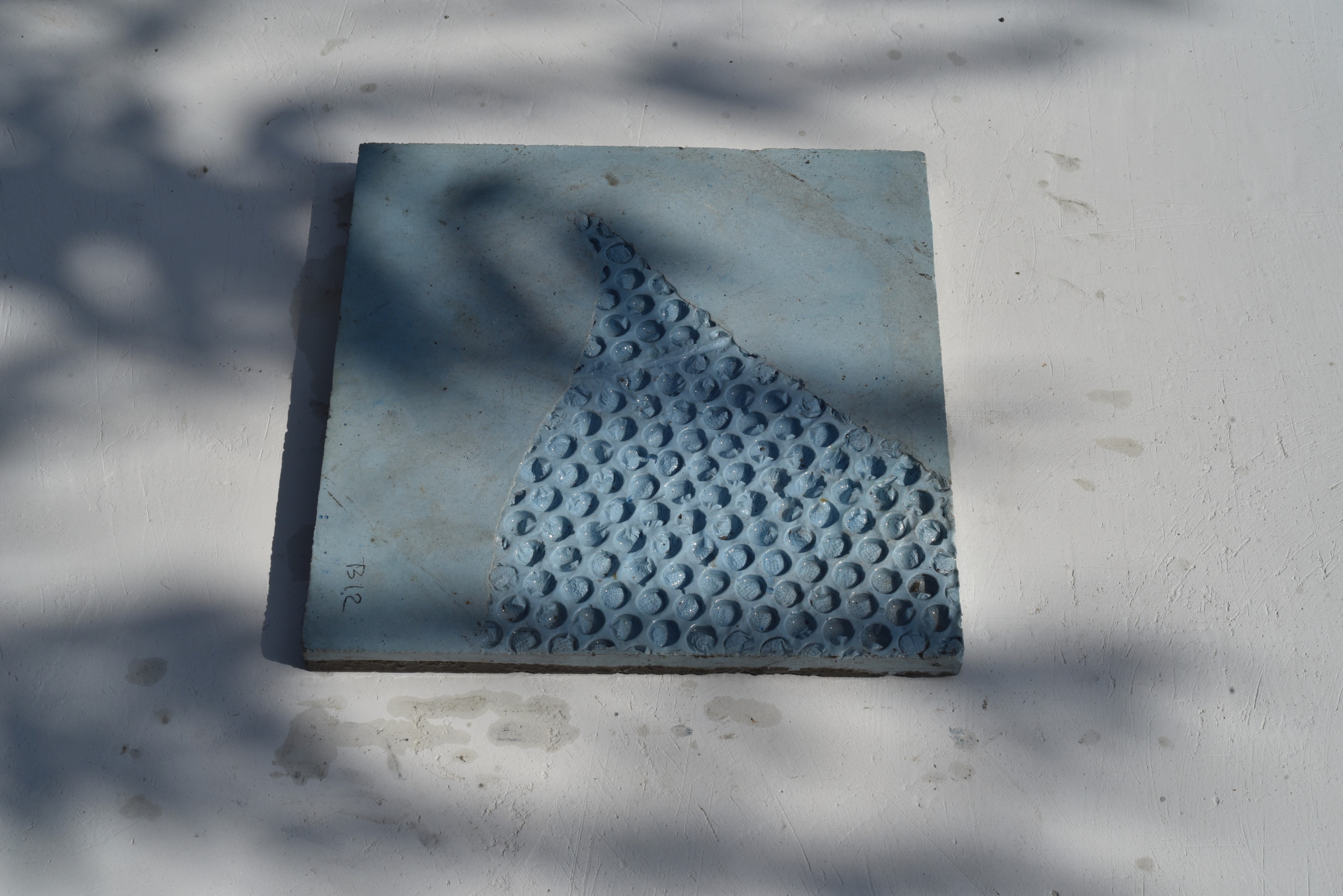

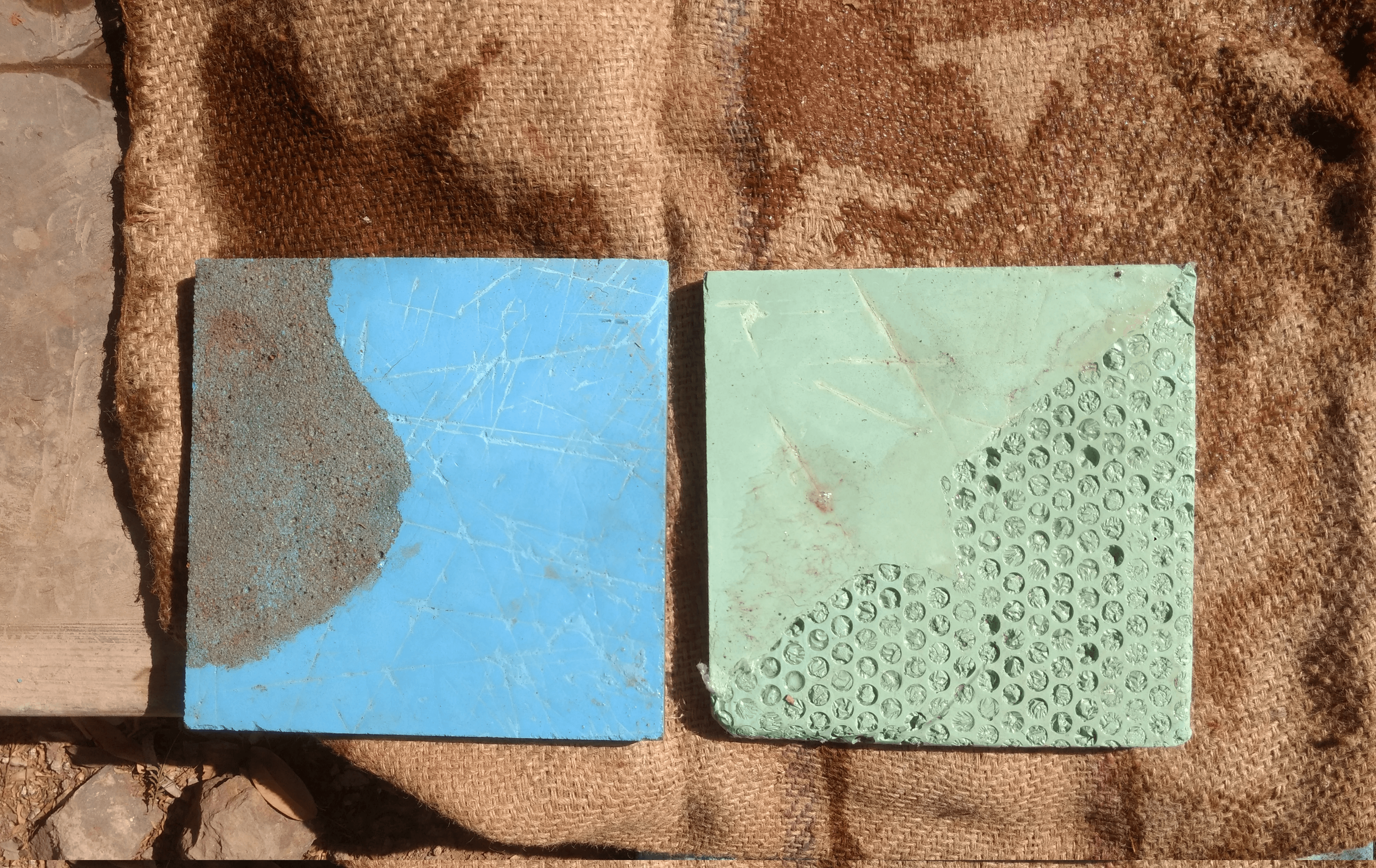

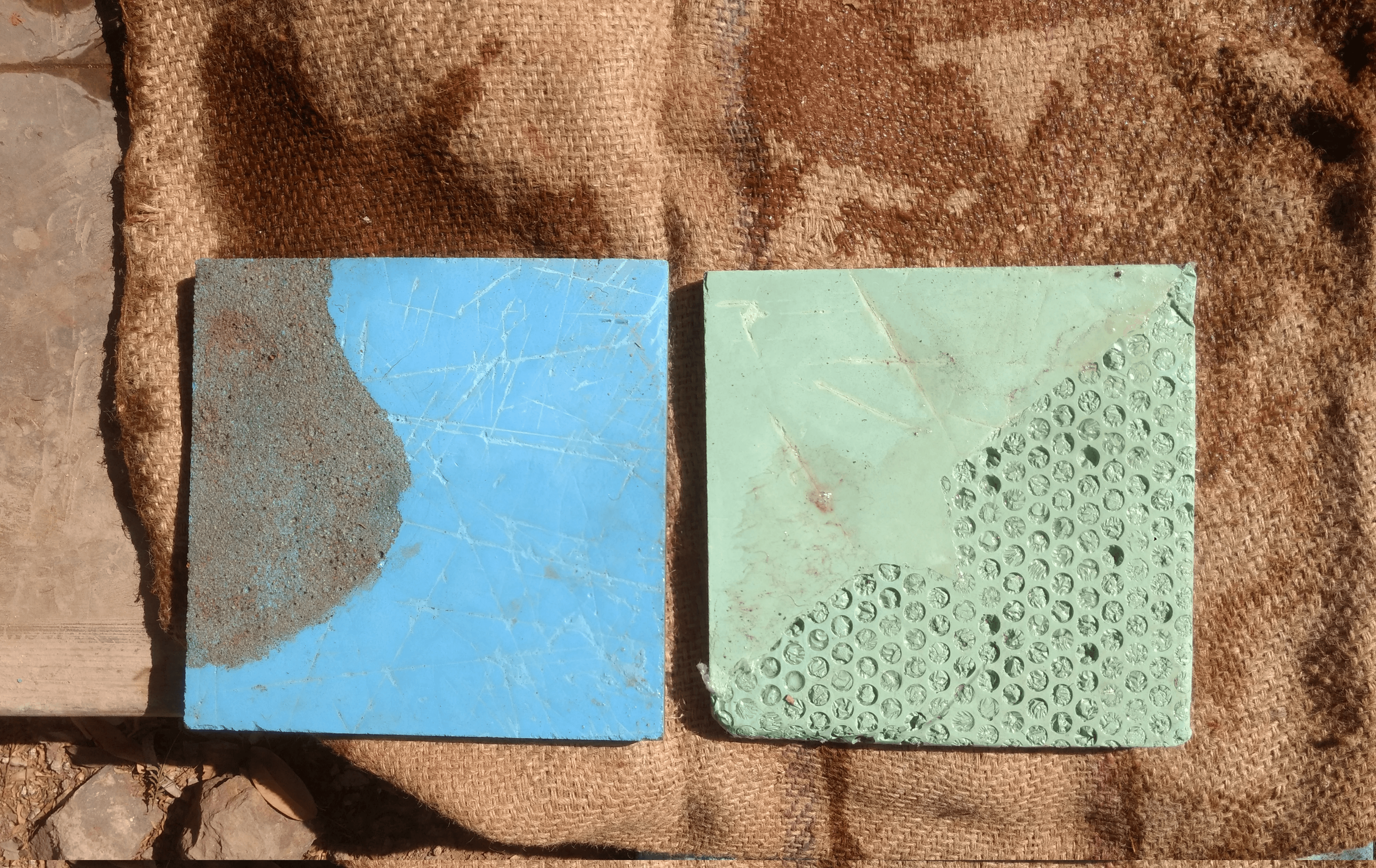

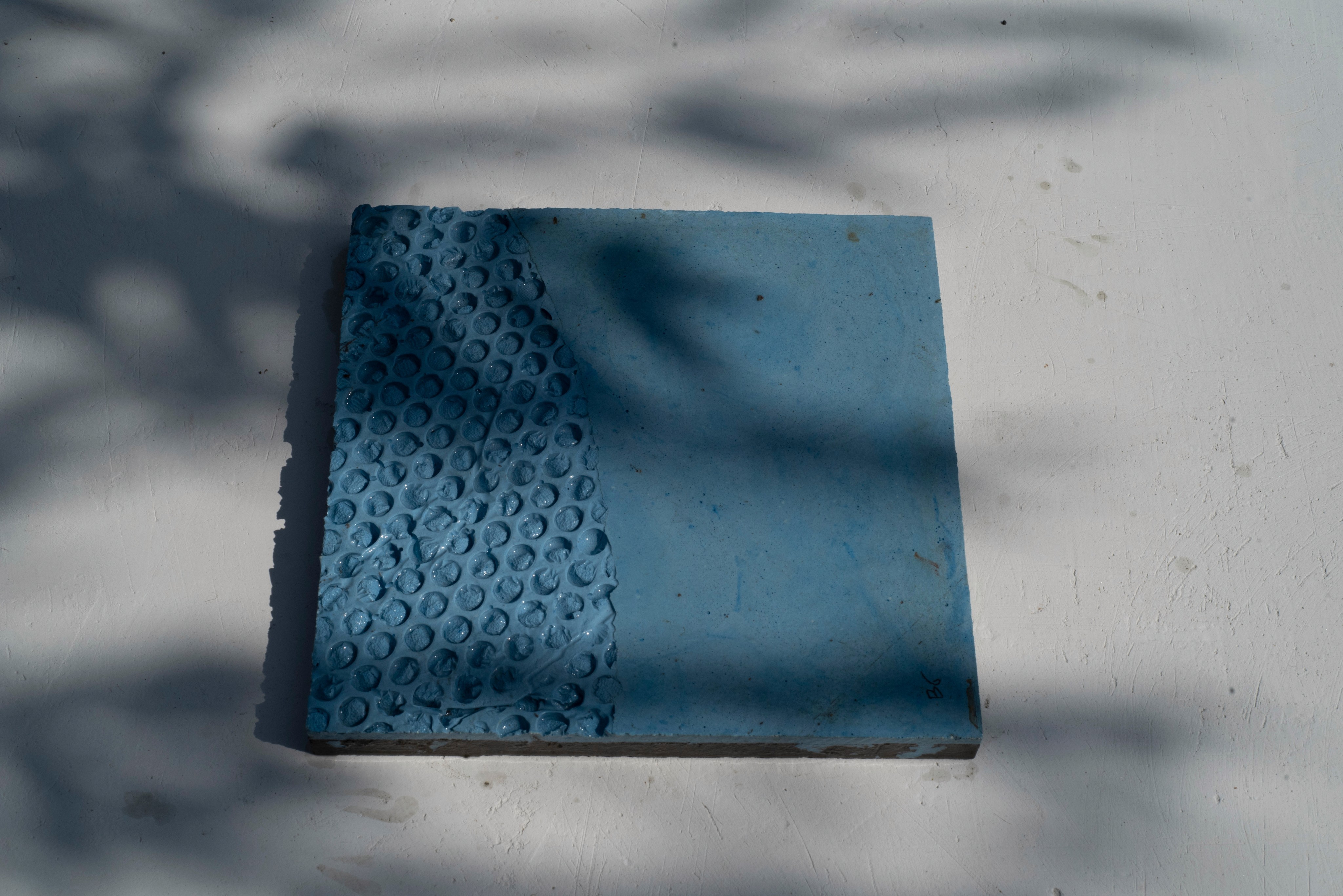

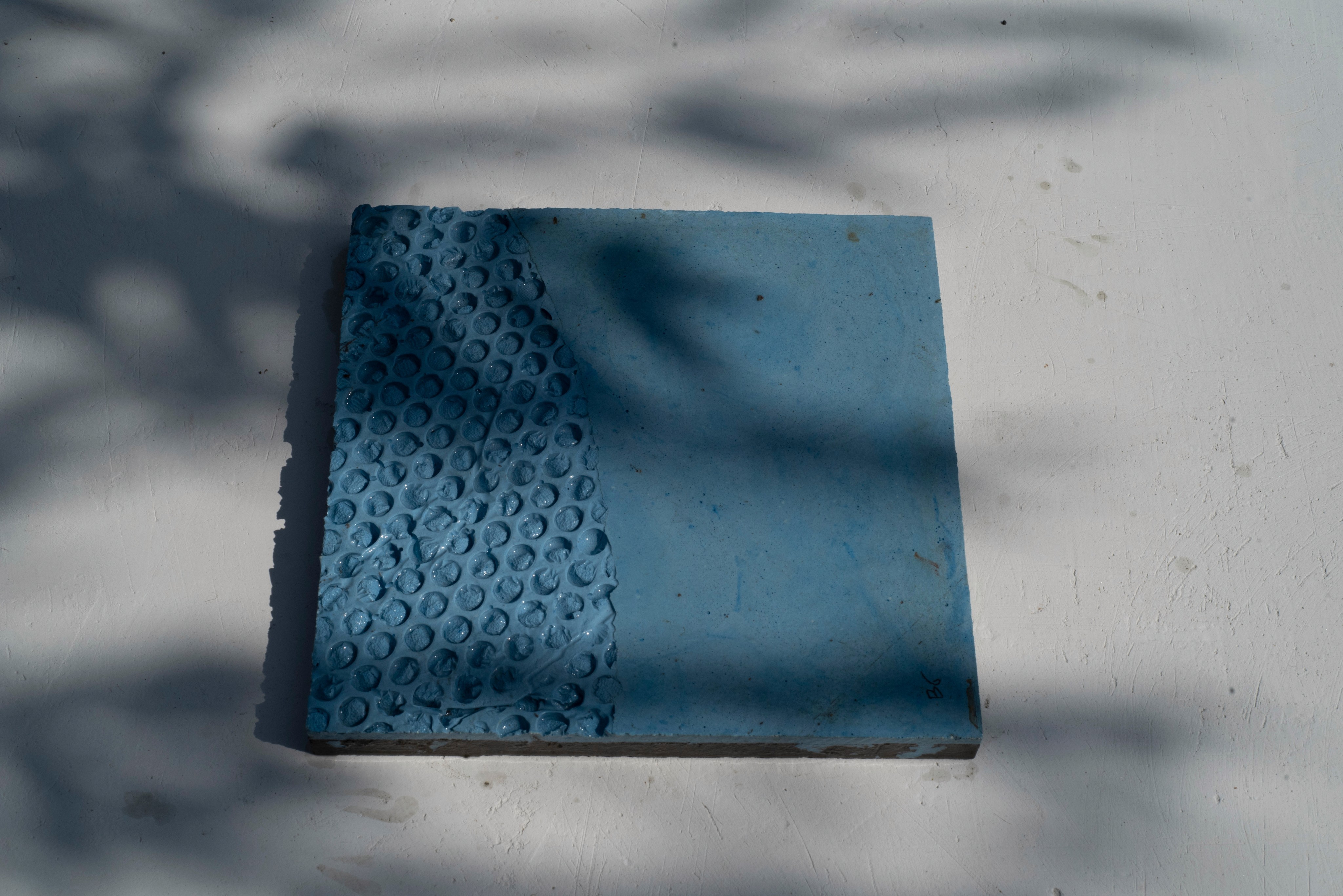

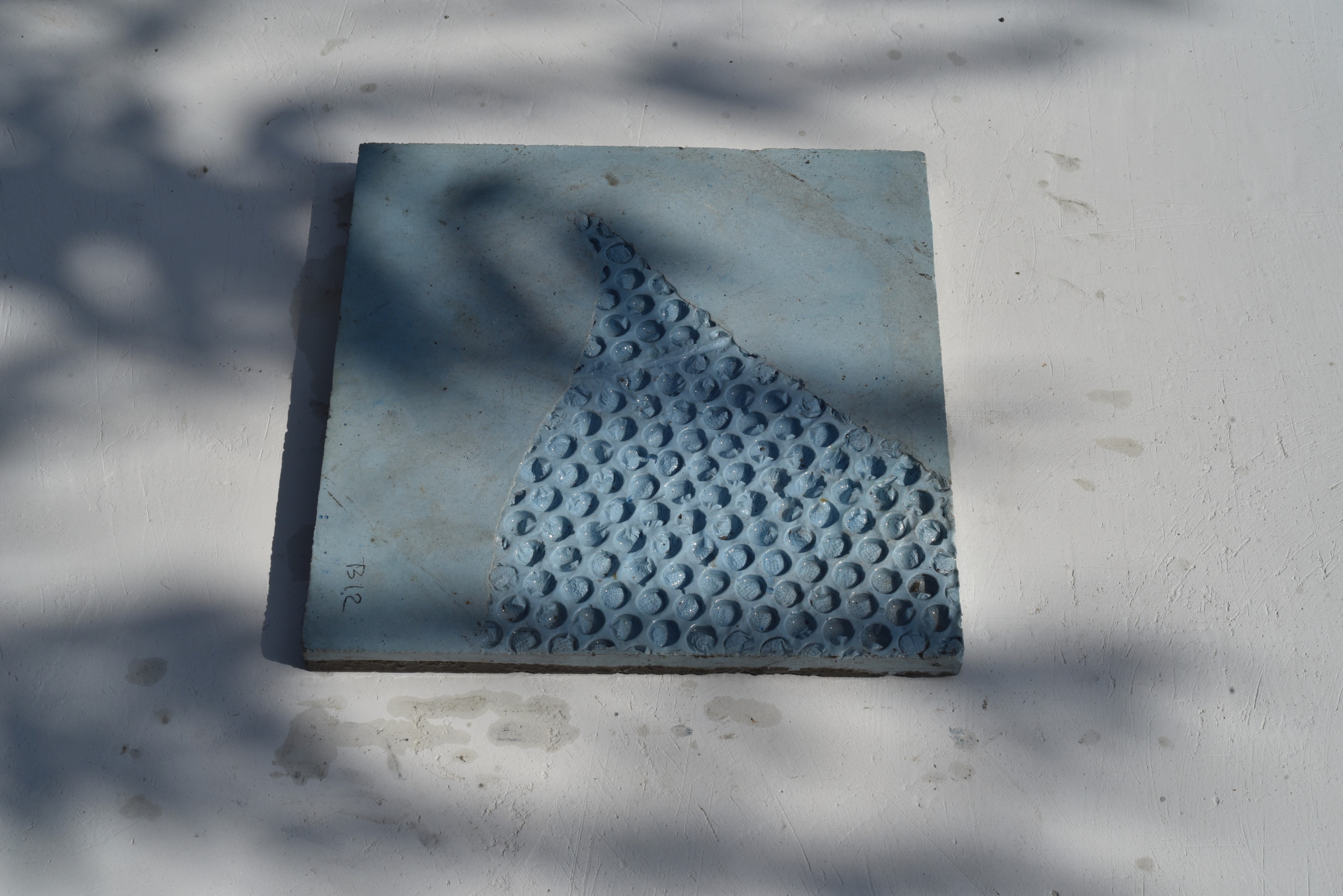

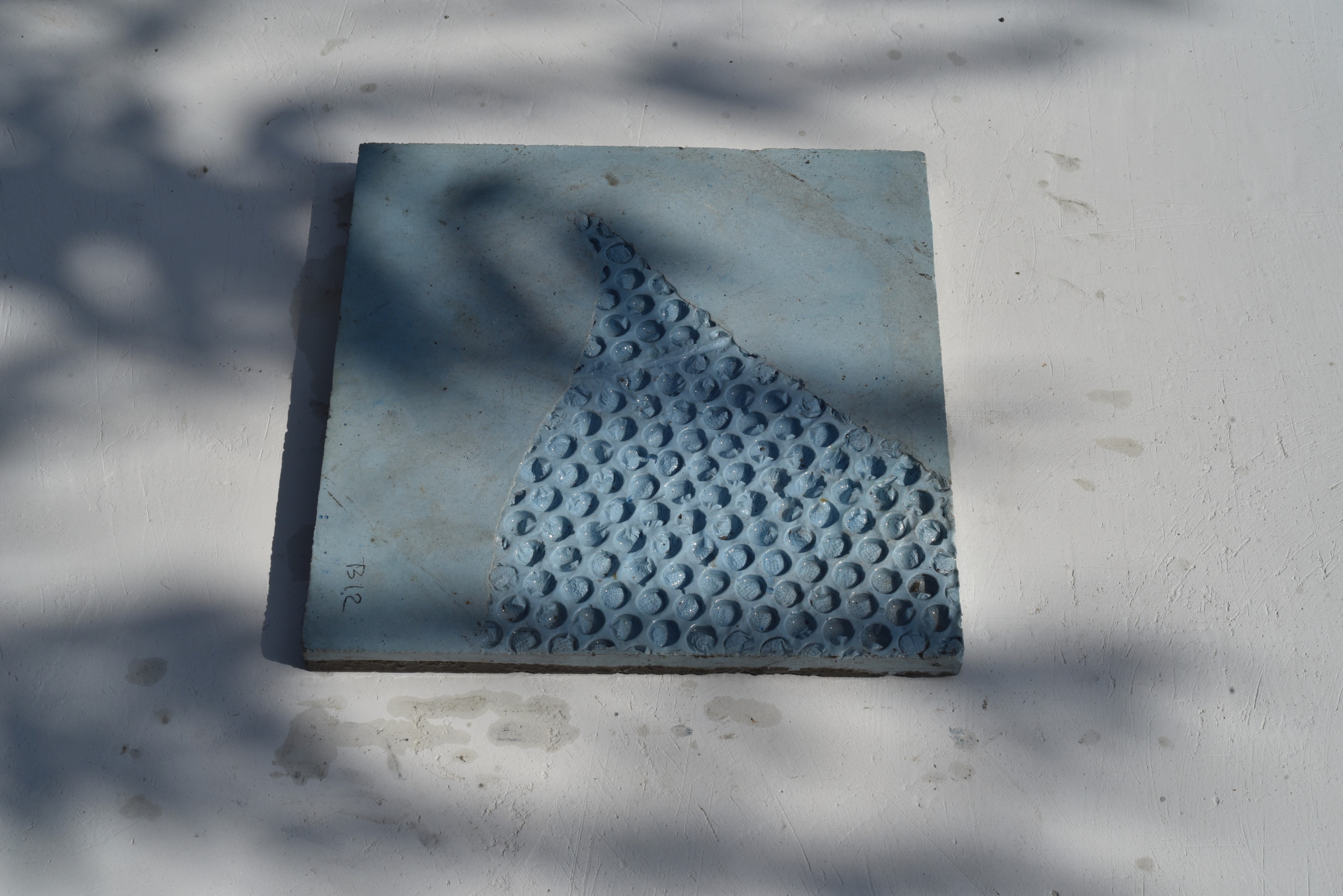

Pattern exploration through bubble wrap and sand casting

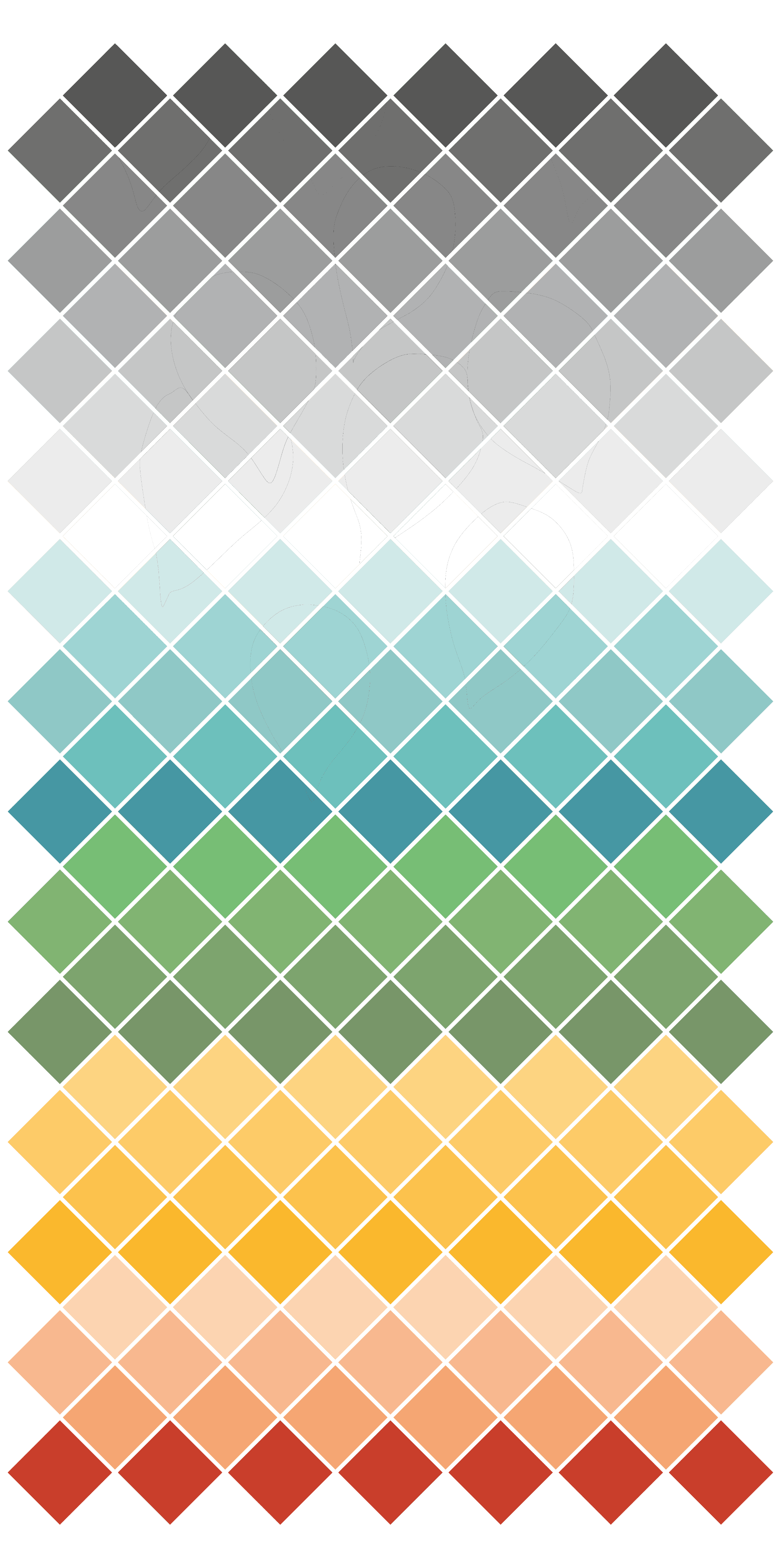

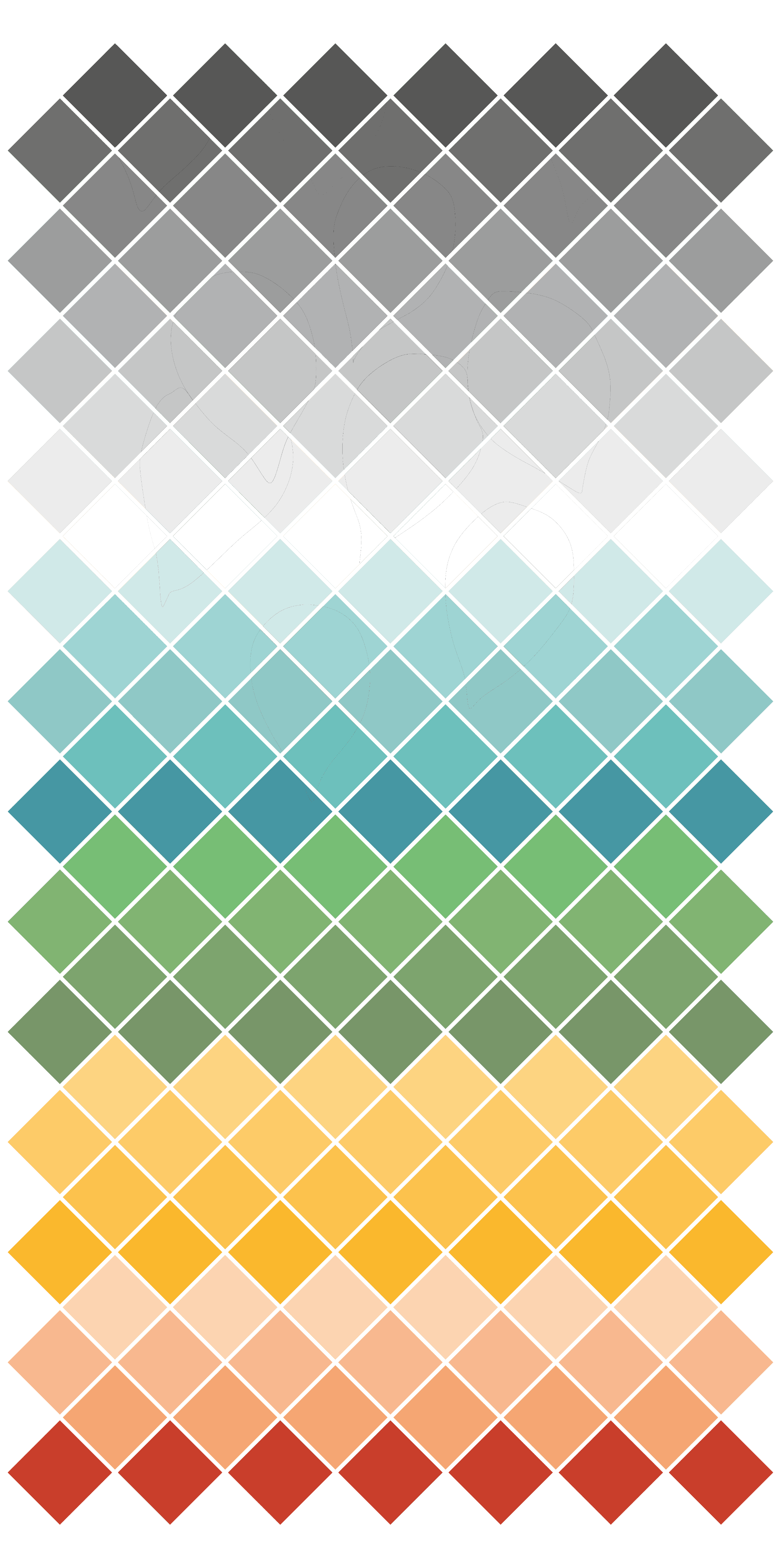

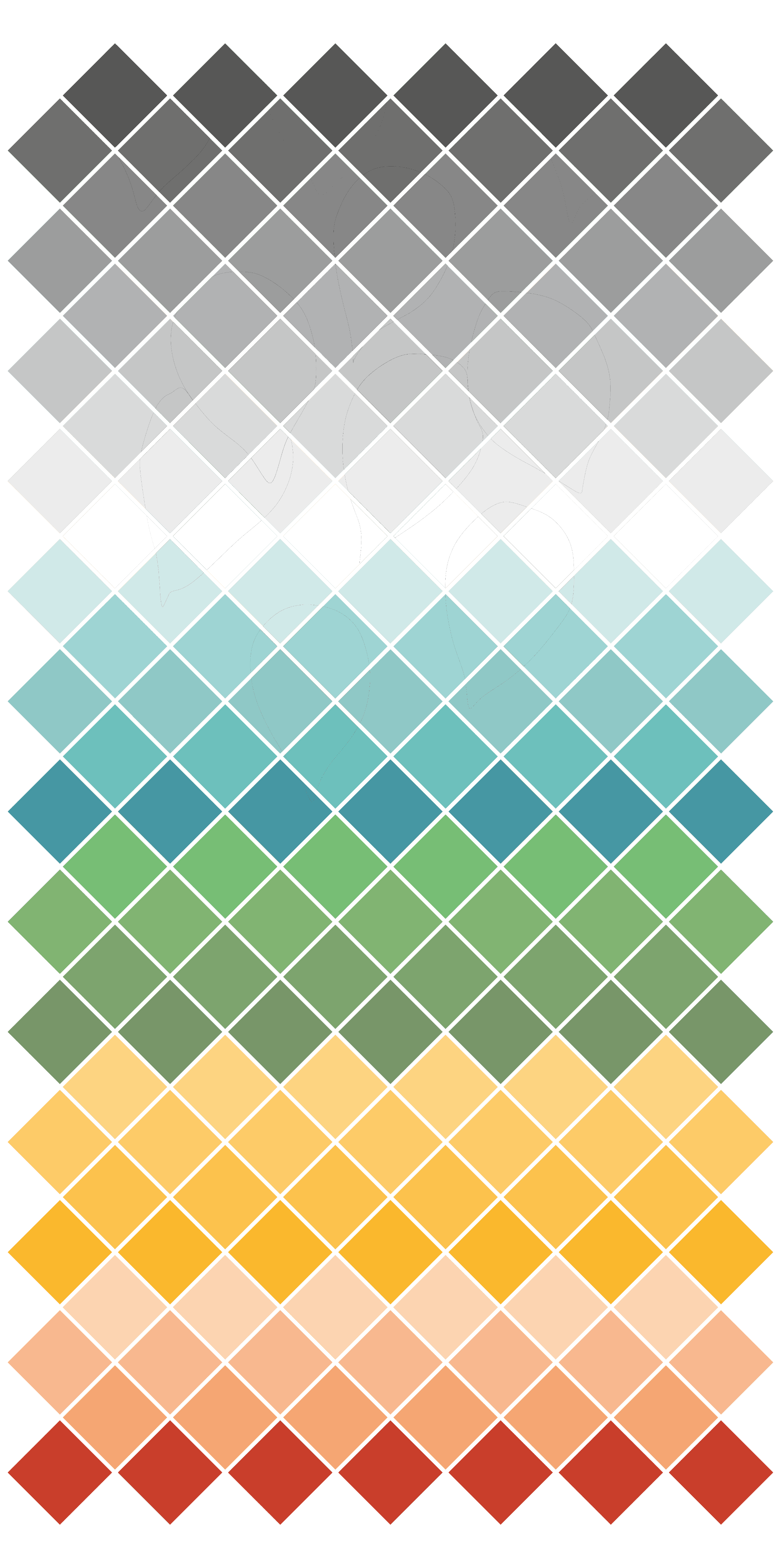

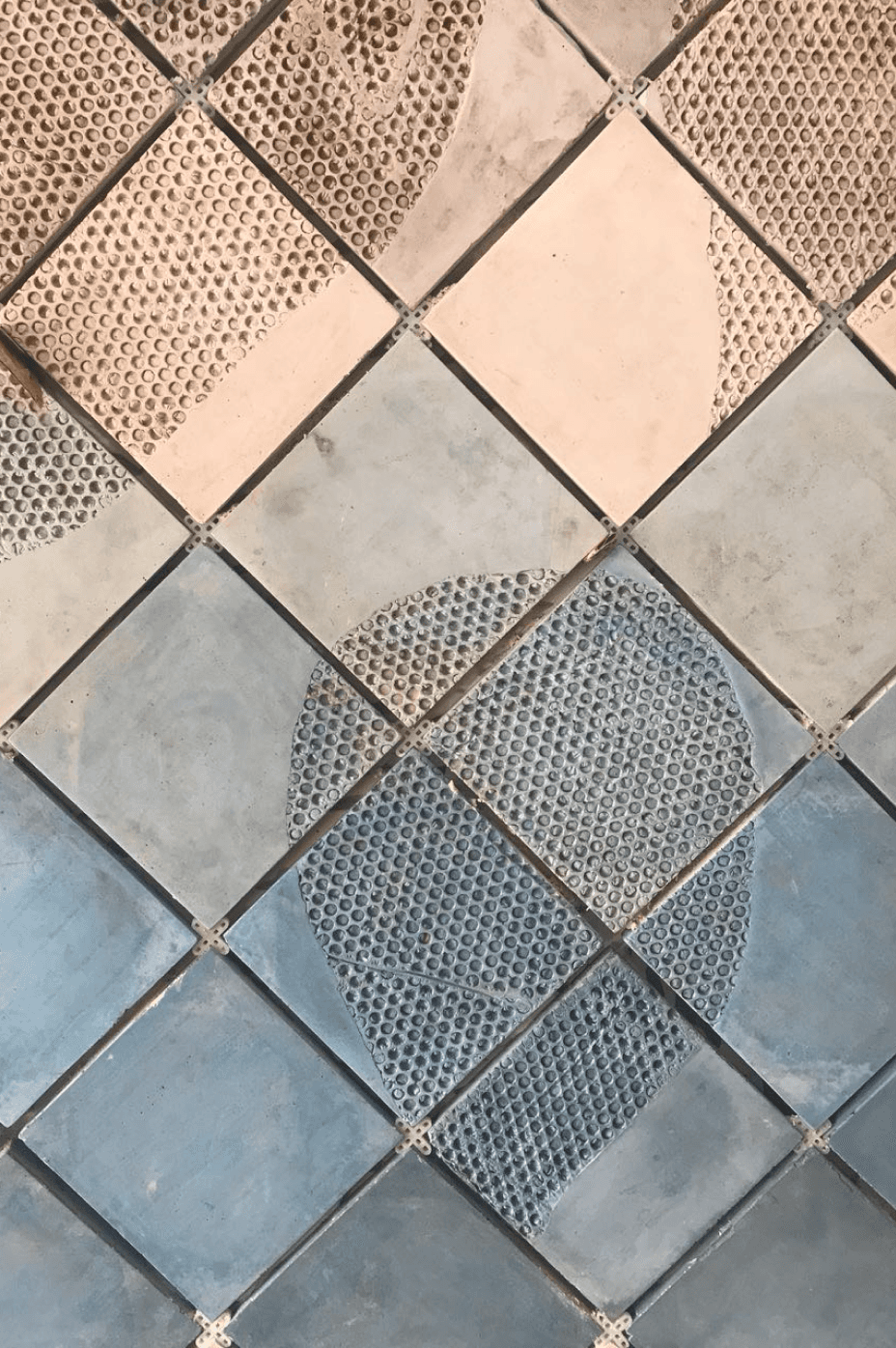

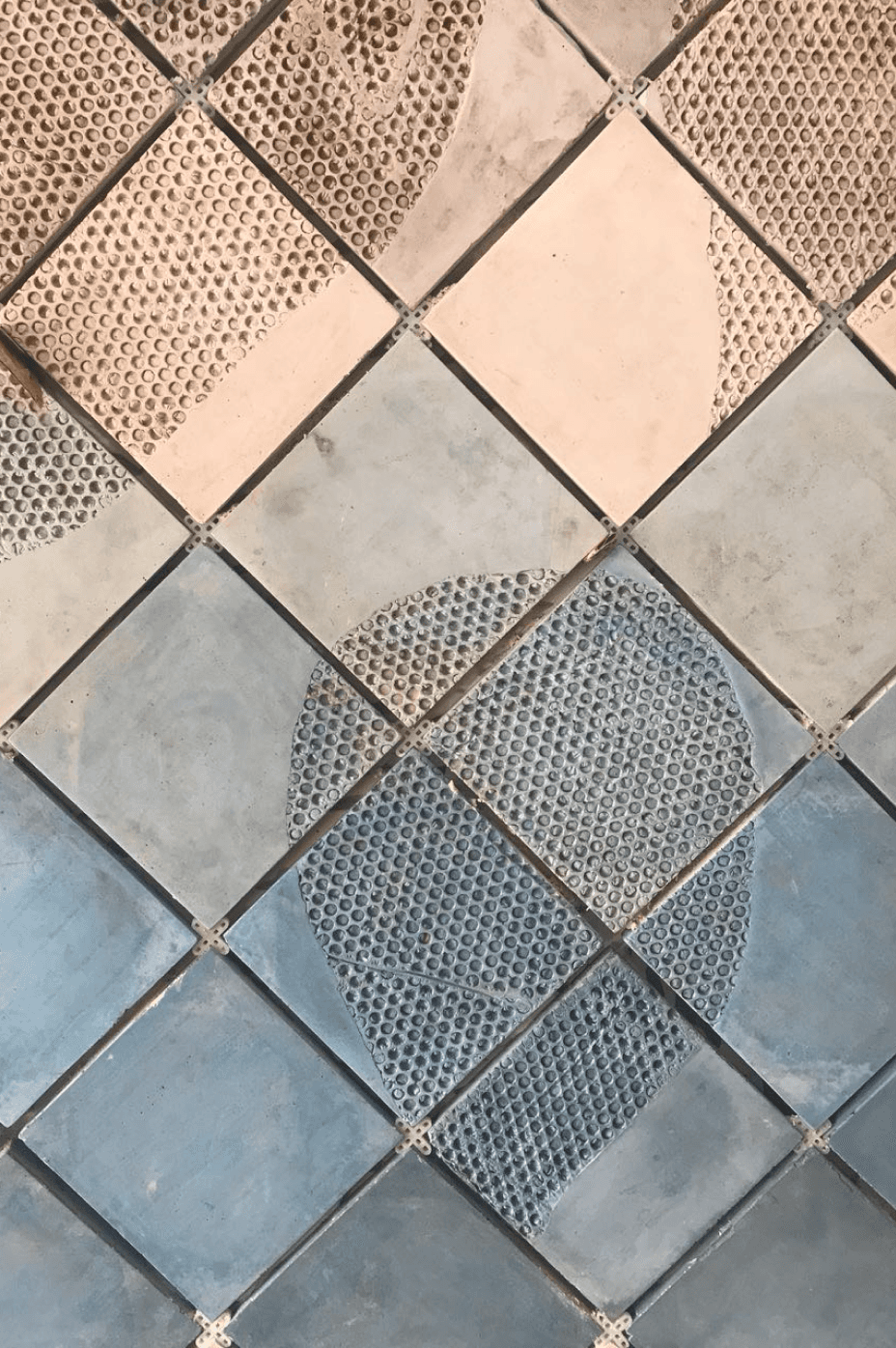

Different shades created from different proportion of the oxide and mixing it with white or gray cement based on required shade

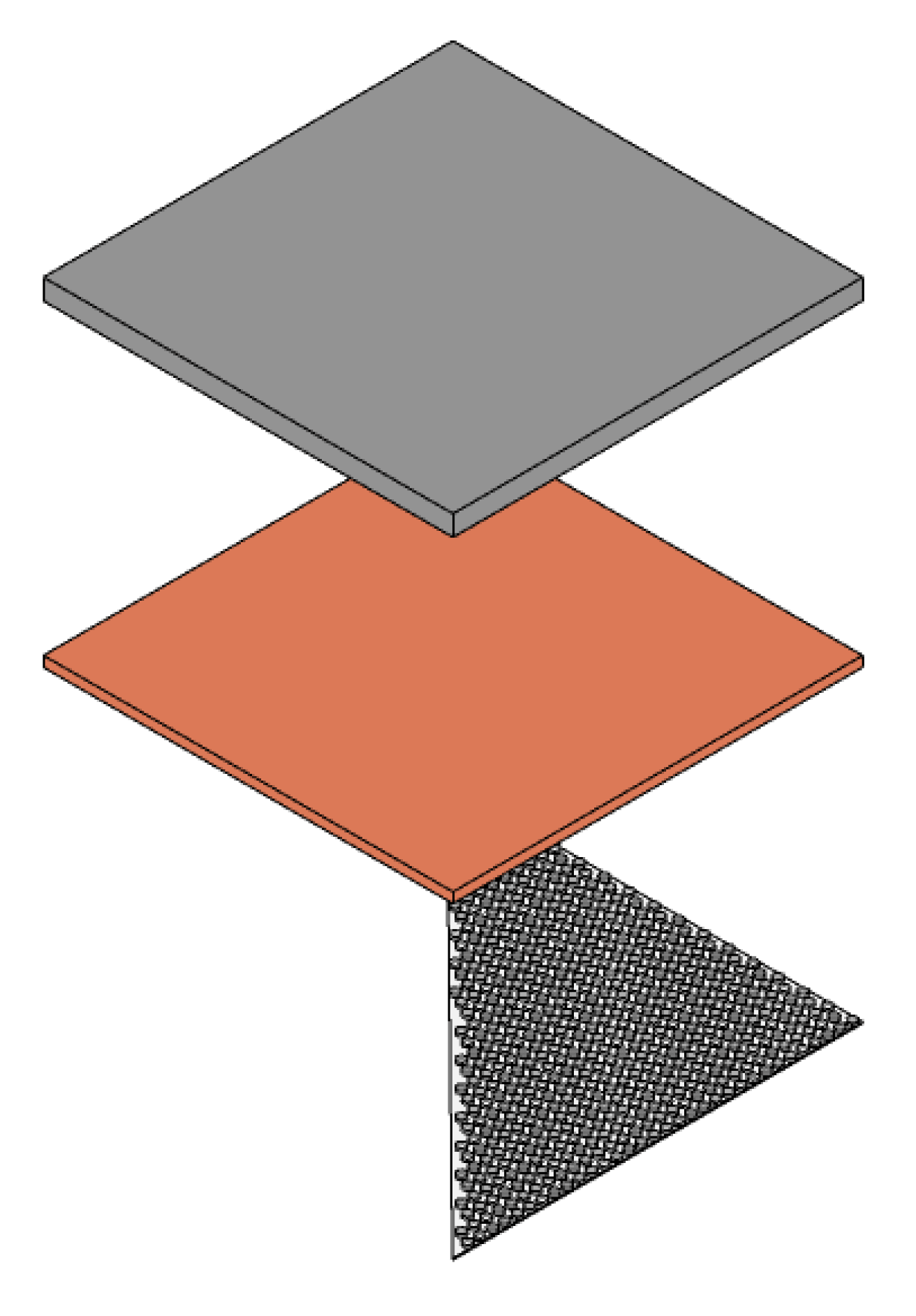

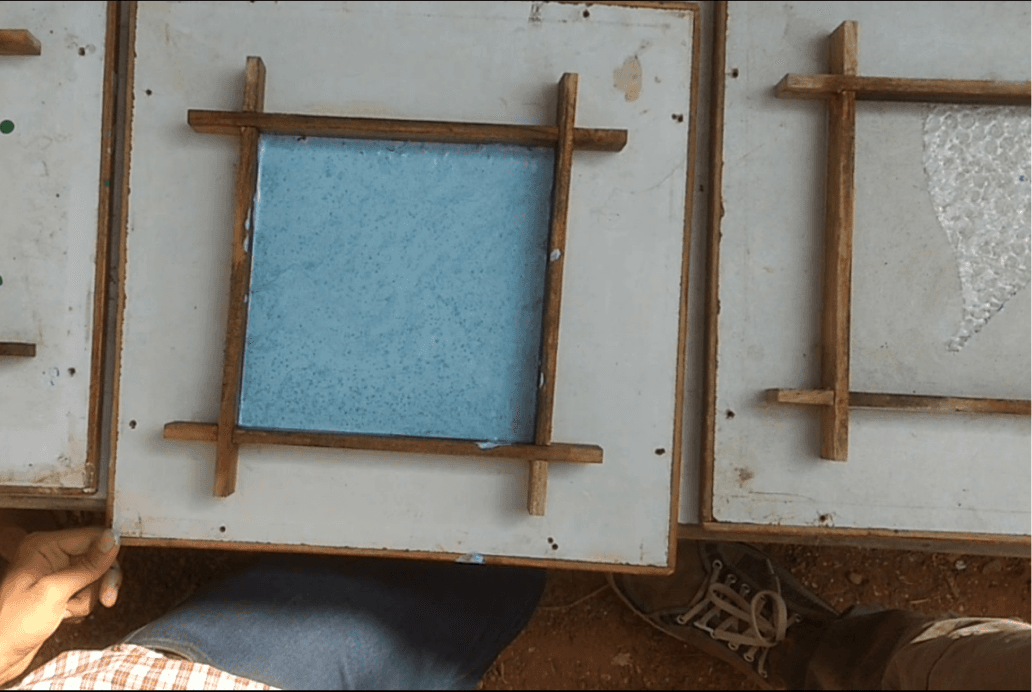

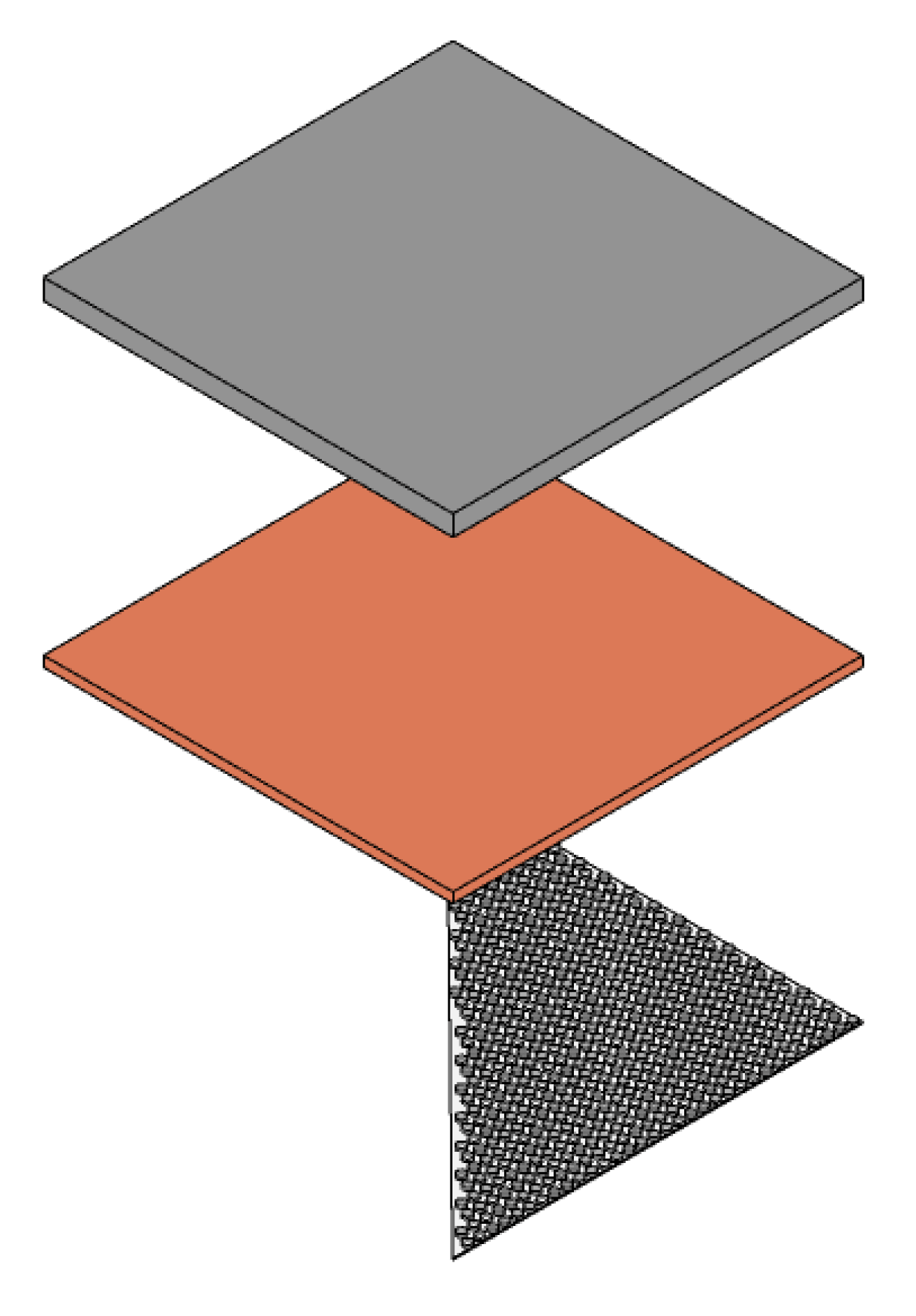

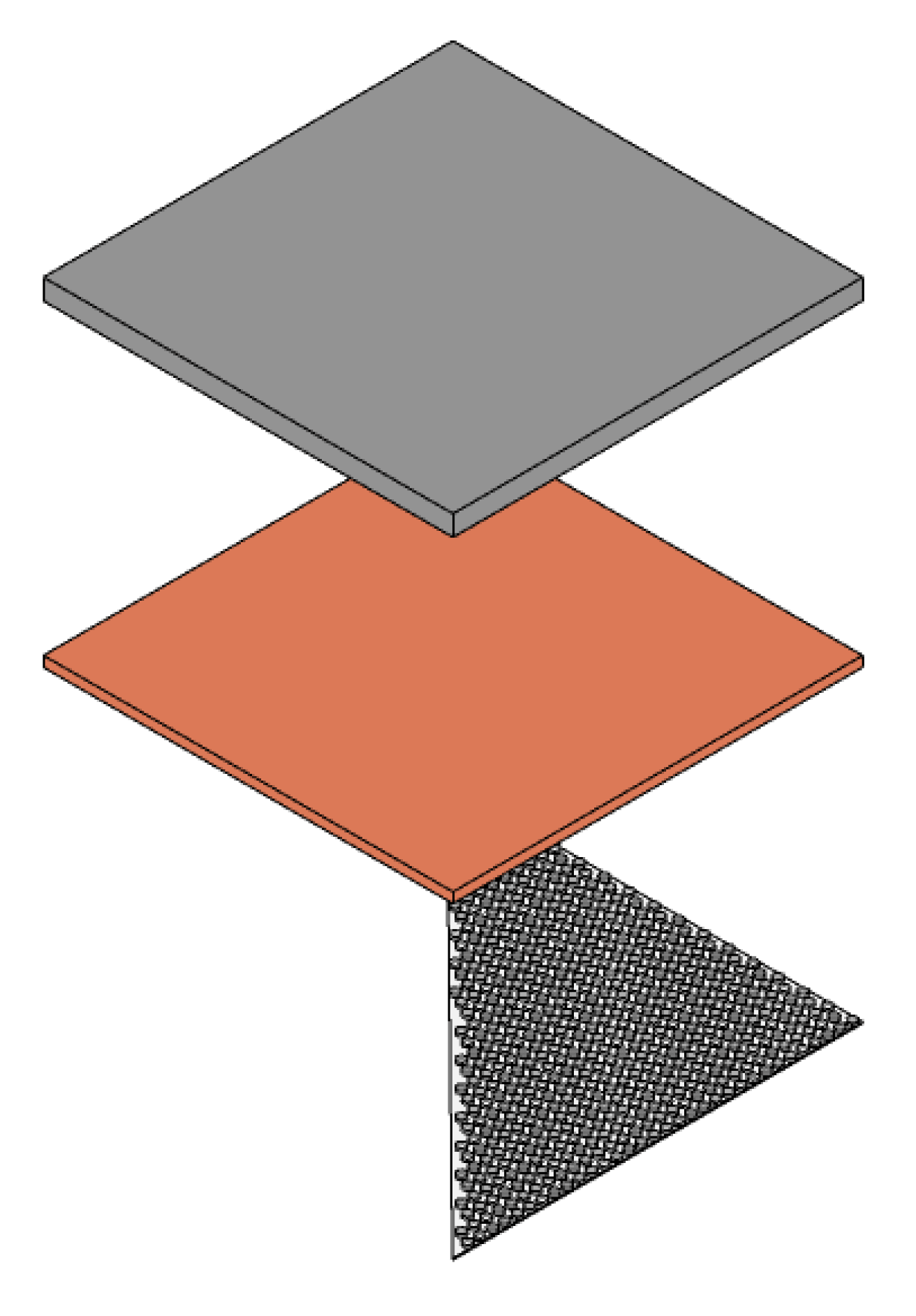

Mortar

Cement Slurry with

pigmented oxide

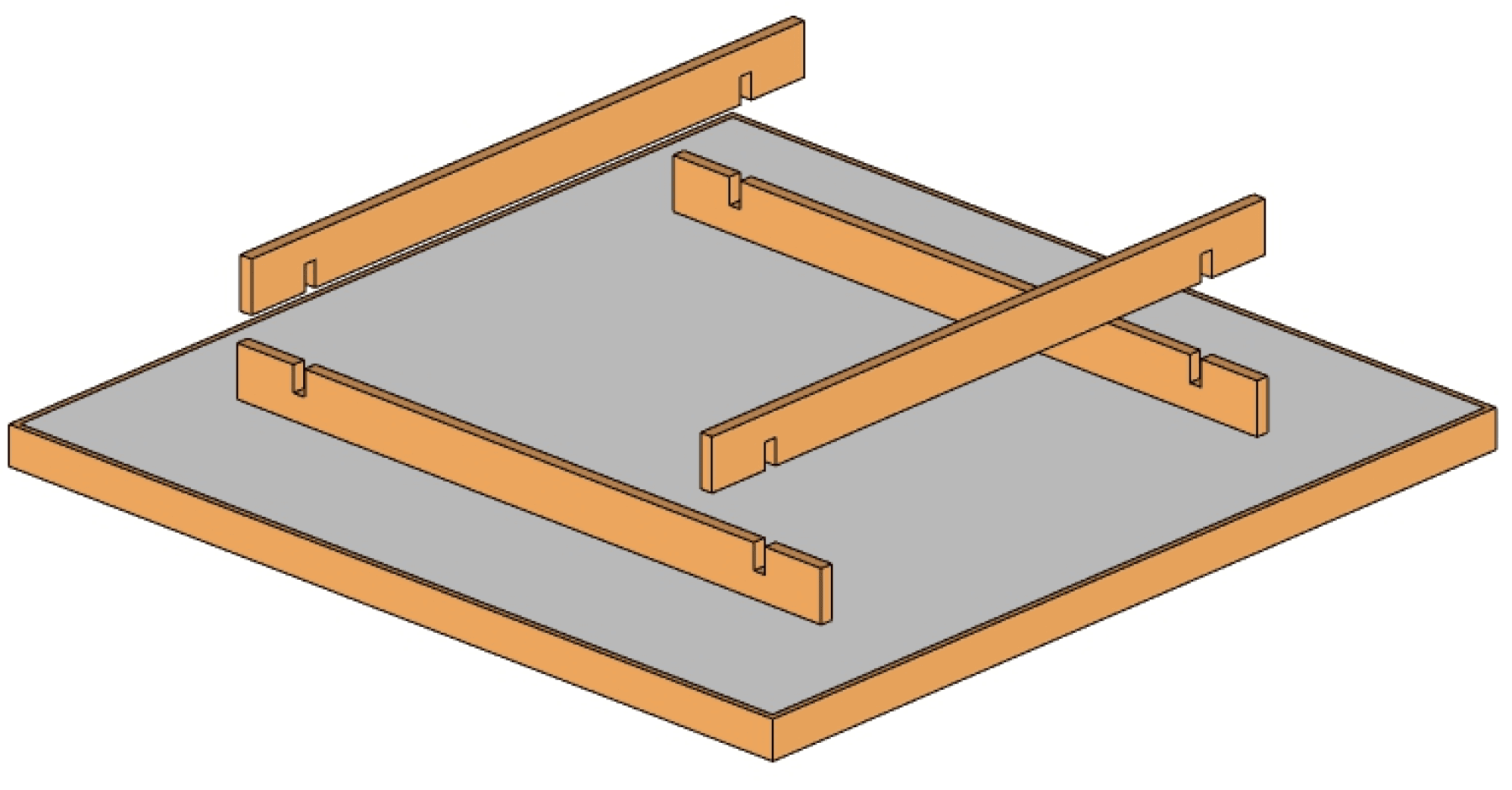

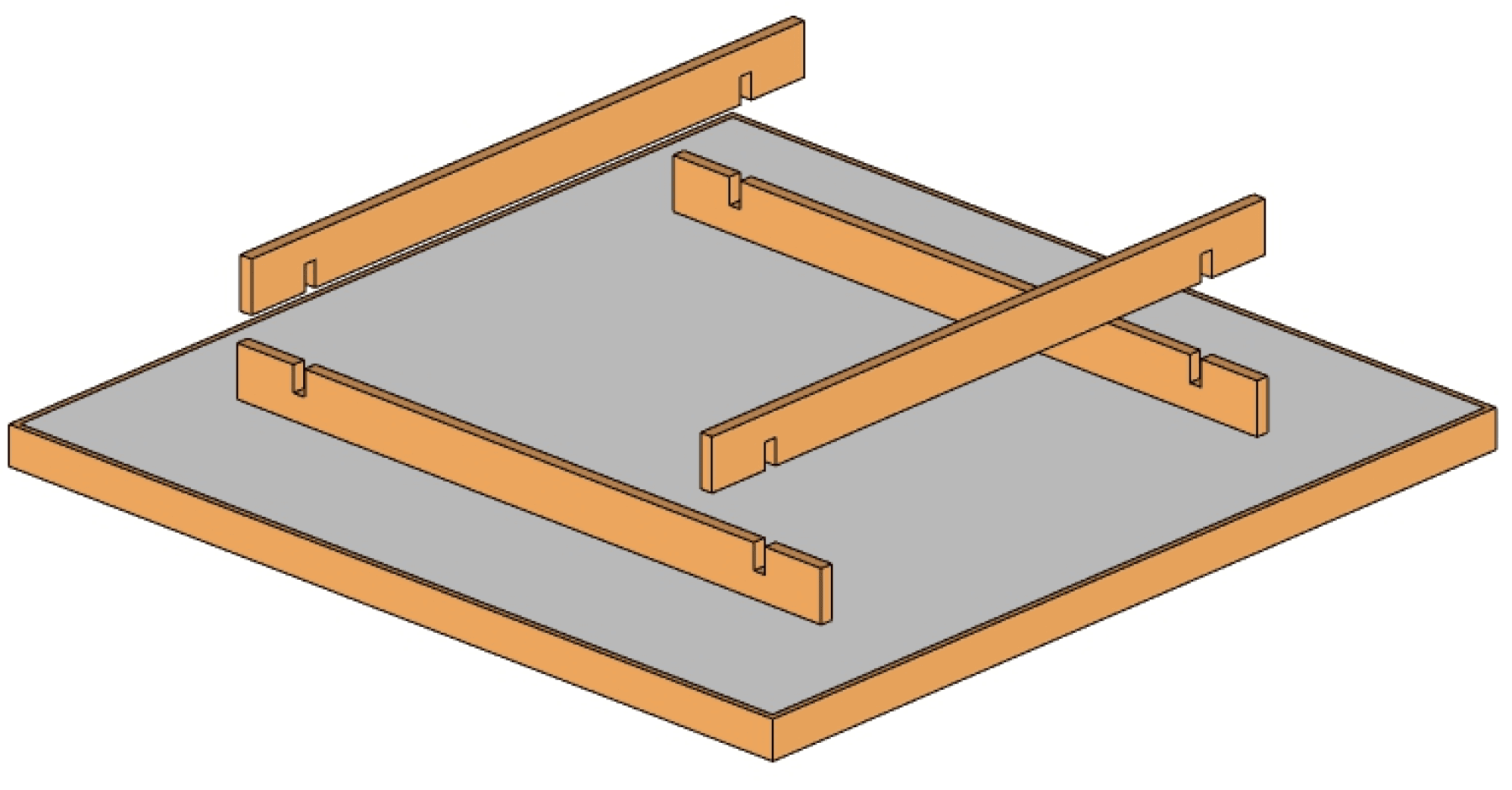

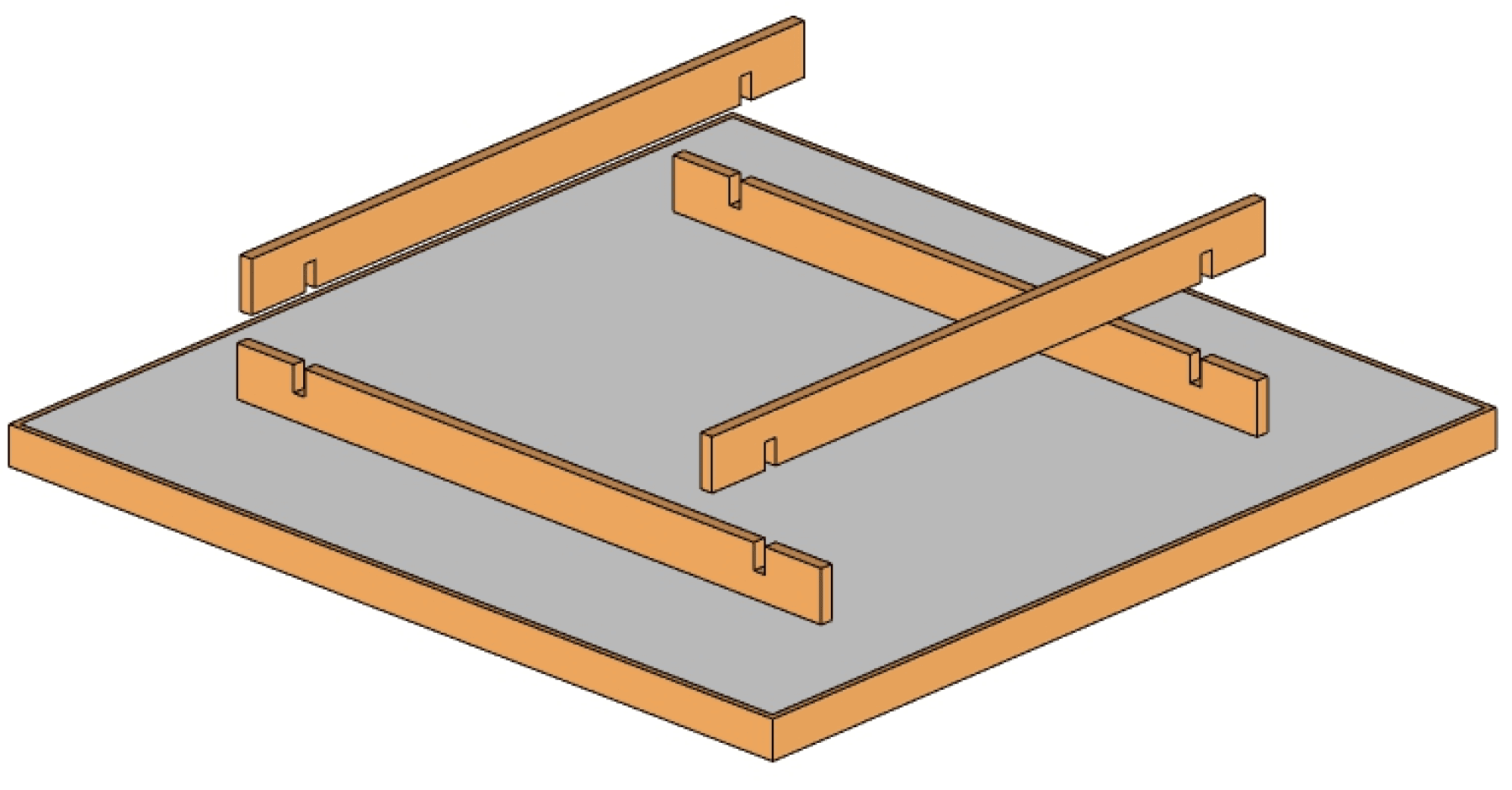

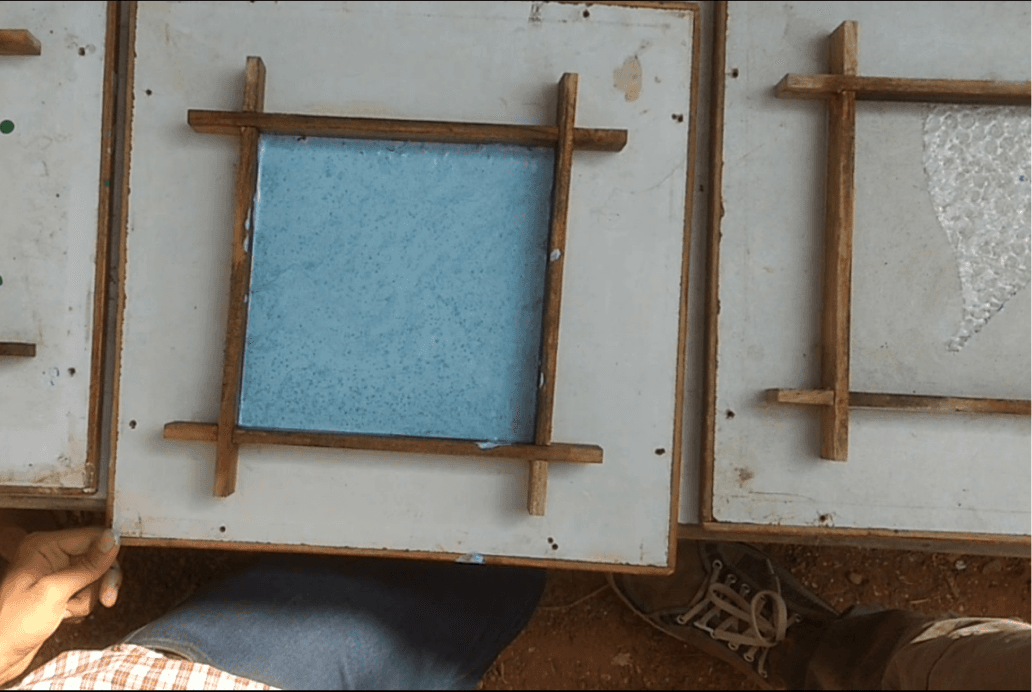

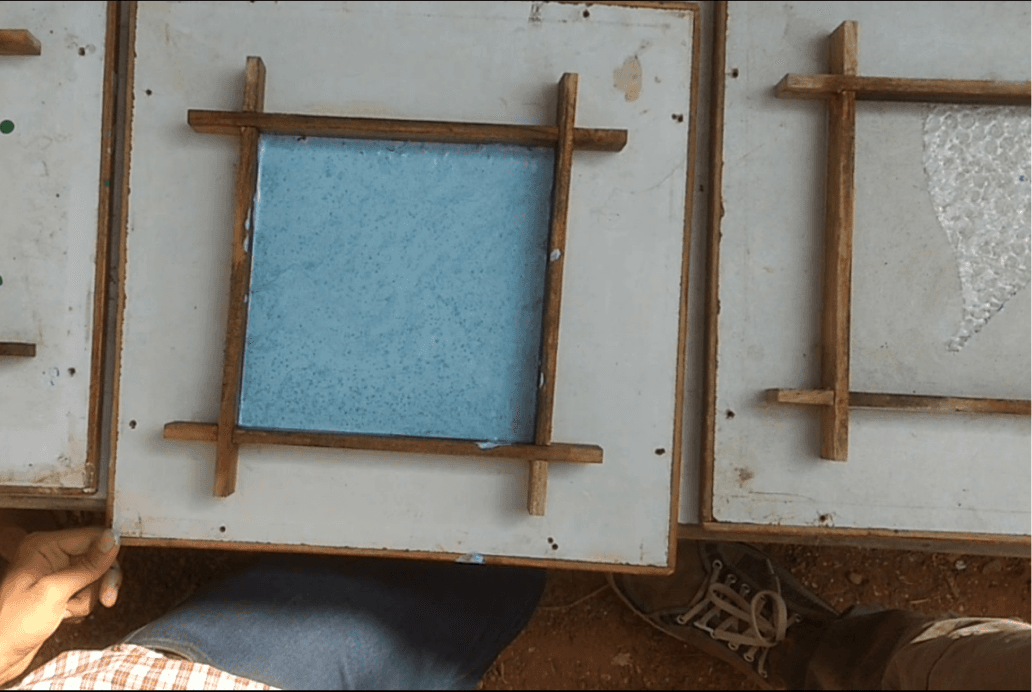

Wooden Frame

Wooden Base

Rubber Glue

Casting sequence

Bubble Wrap

Preparing dry mix consisting of gray/white cement and oxide

Casting the top pigmented layer

Preparing and casting mortar layer

Opening the mould

Challenges and their solutions in the Process

Bonding between the top slurry layer and bottom mortar layer.

Casting in the morning and evening to increase the settling time

Using admixture to improve workability of cement.

To achieve the right shade of the slurry

Preparing the dry mix samples of the shades and using it to achieve the right shade during the production

Achieving workability in the mortar without loosing the strength.

Using admixture to achieve the workability and increase the setting time

Broken corners while removing the mould.

Taping the mould while casting to remove the trapped air, making the cast uniform

Wrapping the freshly casted tile in jute cloth and curing it to retain the water

Applying the burnt oil on the wooden frame especially at the corner junctions, so the cement doesn't bond with the base

Shade of the tile and pattern on it after removing it from the mould

Polishing the tiles to have matte finish and to reduce the roughness

Labeling each row of tiles on site for ease of execution

Wooden Beading were provided in the spacing to support the tiles

Final Outcome

Click to see more photos

Learnings

This project helped in gaining a thorough understanding of Cement’s characteristics like its setting time, finish, workability and strength with respect to proportion. These understanding is valuable for identifying causes of problems in concrete construction.

Small details like casting time, vibration, water quality, sequence are very important in achieving the desired finish. These details can be known through research but being physically involved in the process would provide a more relevant information of the system.

As it was our first experience with such a project, we were not aware about all the expenses that we would have to bear. And thus it taught a lot about allocating right amount of resources in each process and how to charge for the service.

Brief

Casting cement tiles of different shades in gradation for a 3' x 6' wall mural in a ceramic import export office

Hands on

The process included experimenting with cement, various shades of oxide, different ways to create pattern on the tiles.

Pattern exploration by casting different leaves

Pattern exploration through bubble wrap and sand casting

Different shades created from different proportion of the oxide and mixing it with white or gray cement based on required shade

Mortar

Cement Slurry with

pigmented oxide

Wooden Frame

Wooden Base

Rubber Glue

Casting sequence

Bubble Wrap

Preparing dry mix consisting of gray/white cement and oxide

Casting the top pigmented layer

Preparing and casting mortar layer

Opening the mould

Challenges and their solutions in the Process

Bonding between the top slurry layer and bottom mortar layer.

Casting in the morning and evening to increase the settling time

Using admixture to improve workability of cement.

To achieve the right shade of the slurry

Preparing the dry mix samples of the shades and using it to achieve the right shade during the production

Achieving workability in the mortar without loosing the strength.

Using admixture to achieve the workability and increase the setting time

Broken corners while removing the mould.

Taping the mould while casting to remove the trapped air, making the cast uniform

Wrapping the freshly casted tile in jute cloth and curing it to retain the water

Applying the burnt oil on the wooden frame especially at the corner junctions, so the cement doesn't bond with the base

Shade of the tile and pattern on it after removing it from the mould

Polishing the tiles to have matte finish and to reduce the roughness

Labeling each row of tiles on site for ease of execution

Wooden Beading were provided in the spacing to support the tiles

Final Outcome

Click to see more photos

Learnings

This project helped in gaining a thorough understanding of Cement’s characteristics like its setting time, finish, workability and strength with respect to proportion. These understanding is valuable for identifying causes of problems in concrete construction.

Small details like casting time, vibration, water quality, sequence are very important in achieving the desired finish. These details can be known through research but being physically involved in the process would provide a more relevant information of the system.

As it was our first experience with such a project, we were not aware about all the expenses that we would have to bear. And thus it taught a lot about allocating right amount of resources in each process and how to charge for the service.